by Justin Hawkins

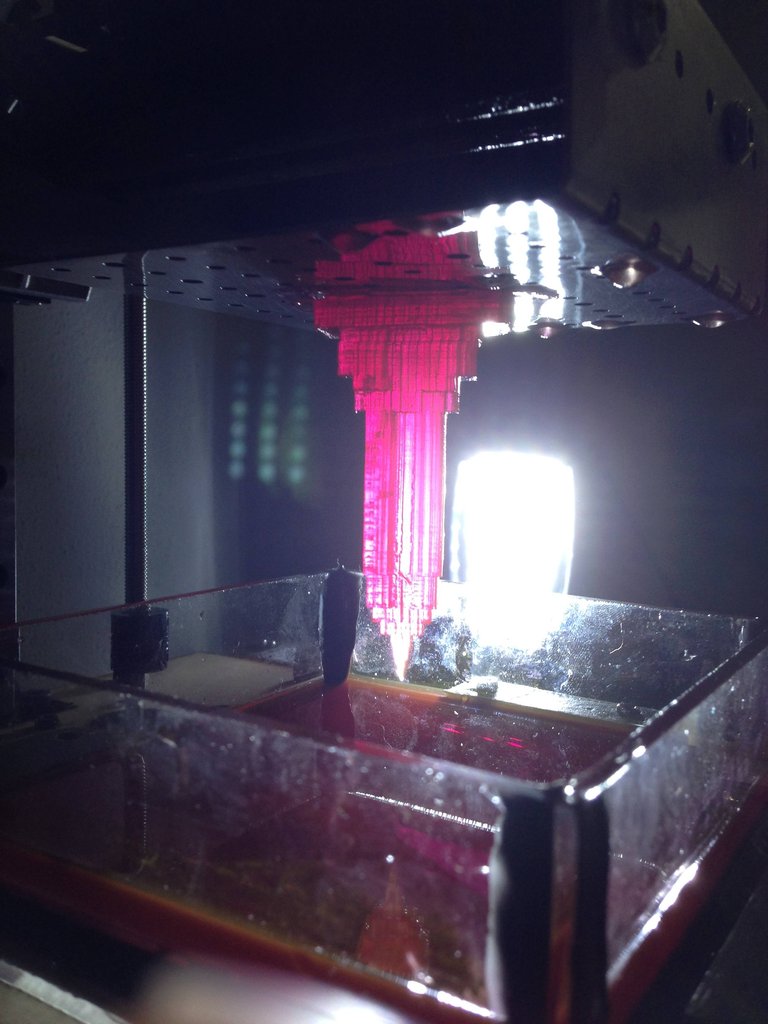

Stereolithography has been around for years. The art of taking uncured liquid resin and pulling out solid objects, while amazing, is not itself a new technology. In fact, its origin dates back to the seventies.

Why then has such an amazing technology that has immense potential been so inaccessible to the general public? Stereolithographic printers cost upwards of up to 200,000 dollars for printers the size of a compact car. On top of that, the print material these devices use is inaccessible due to cost and toxicity.

For the past year, the team of Pryntech has been working on an open hardware design for a high resolution stereolithographic printer. The printer has both small physical and environmental footprints — it utilizes VOC Free UV curable resin and fits naturally on your desk with a beautiful 20cm square base and 35cm height.

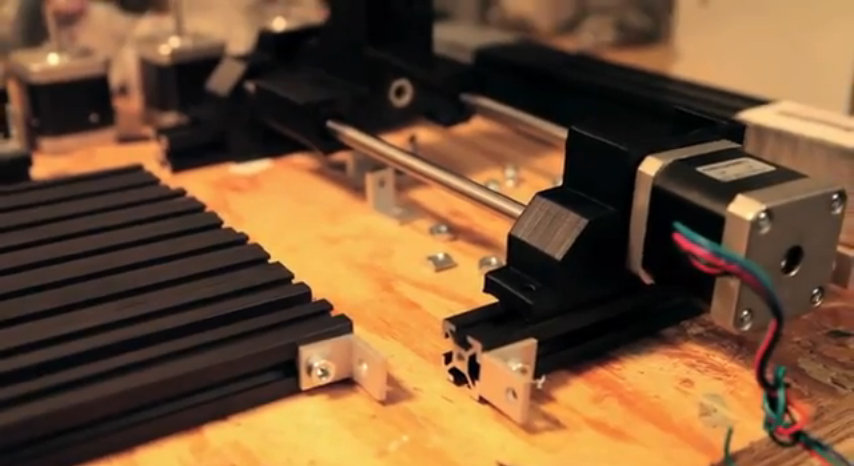

When the inventors were designing the printer, they put a lot of thought into where the hardware of this printer should come from. They focused on keeping the part count as low as possible and allowing for as many off-the-shelf parts as possible to make it easy to source and build. For the parts that aren’t off-the-shelf, Pryntech provides a complete set of design files that you can take to your local hackerspace and turn into all the components required for a functioning printer.

The printer runs off existing open source software used by existing FDM (Fused Deposition Modeling) printers. Having the source open has allowed us to make the slight modifications to the software required to make it usable for Stereolithography. This has allowed the people of Pryntech to benefit from the advantages that Stereolithography has to offer over existing FDM printers — ultra-high resolution 3D printing.

By keeping the design of the printer open, Pryntech is encouraging others to push the technology even further. And as they say: We live in a world driven by change and innovation – keeping the design inaccessible we would be like putting a period at the end of Stereolithography.